Designed from the ground up specifically for abrasivejet control, MAKE controls your OMAX or MAXIEM JetMachining Center by sending precise motor control commands to move the nozzle along your tool path, while simultaneously controlling the flow of abrasive and high pressure water. By applying advanced internal cutting models, and using built-in compensations for speed, acceleration, and jerk, MAKE is able to provide exceptional results in rapid high-precision abrasive waterjet machining. Advanced corner and piercing optimizations are also automatically applied, for even greater cutting speed and precision.

Cutting edge features in MAKE expand abrasive waterjet machining potential, such as precise computer control of the jetstream pressure to allow for piercing of brittle materials and advanced taper reduction methods that deliver extraordinary cutting precision and speed. Because MAKE cuts the part in software first before sending it to the machine, the comprehensive and highly detailed part time estimates, job quoting and reporting features are precise down to fractions of a second. These reports can be created from your desktop or laptop computer, away from the machine.

Features & Benefits

- Fourth generation cutting model

- Optimal stack height calculator

- Special cutting quality for minimum taper

- Accurate part machining time estimating

- Automatic detection of potential collision areas and navigation around them

- Standard and custom reports

- History tracking

- Computer-controlled cutting stream pressure allows piercing of brittle materials

- Easily resize, rotate, or flip part for prototyping, or to align with existing features

- Reduce programming time to achieve minimum taper quality with higher precision and speed

- Import from a wide variety of third party CAM programs

- Support manual and array nesting so the end user can easily make multiple copies of the same part while getting the most from the material

- Open file formats, along with free consultation from OMAX, allow nearly any 3rd party CAM system to output to the OMAX

Resources

See OMAX MAKE in Action

Import a Tool Path

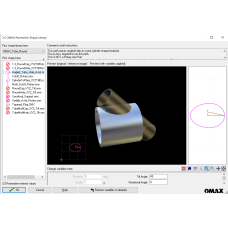

MAKE can open files from many CAD/CAM programs, and some programs such as Intelli-CAM can send parts directly to MAKE.

Set Features and View Reports

Easily verify complex features such as tilts through advanced viewing modes, and receive detailed reports on machining your part.

Cut with Precision and Speed

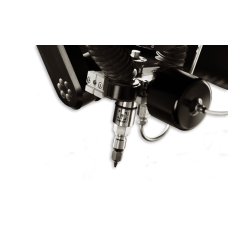

With the click of a button, your OMAX or MAXIEM abrasive waterjet engages its extraordinary cutting power to produce finished parts quickly and precisely.

English

English  Bulgarian

Bulgarian Romana

Romana

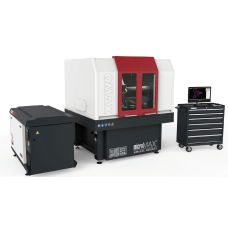

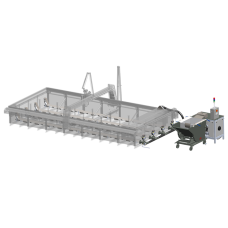

OMAX Micromax

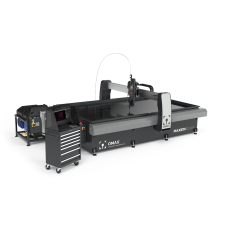

OMAX Micromax OMAX 2626

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

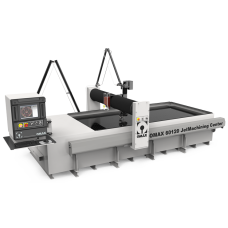

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

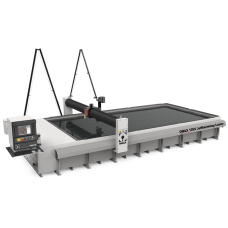

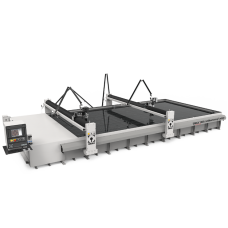

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

OptiMAX 80X MAXIEM 1515X

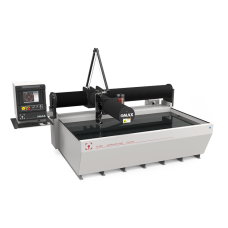

MAXIEM 1515X MAXIEM 1530X

MAXIEM 1530X MAXIEM 2030X

MAXIEM 2030X MAXIEM 2040X

MAXIEM 2040X MAXIEM 2060X

MAXIEM 2060X MAXIEM 3060X

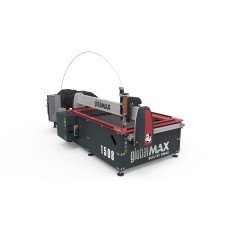

MAXIEM 3060X GlobalMAX 1508

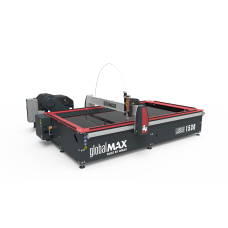

GlobalMAX 1508 GlobalMAX 1530

GlobalMAX 1530 GlobalMAX 2040

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

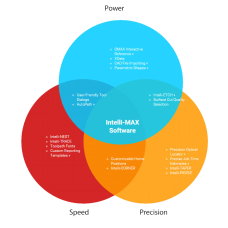

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

Reports Supported File Formats

Supported File Formats Tools

Tools Layout

Layout Make

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program