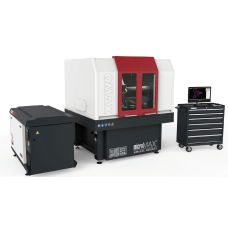

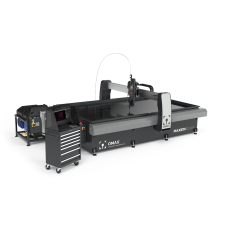

The OMAX OptiMAX 60X is the culmination of three decades of engineering expertise and experience, resulting in the world’s most accurate waterjet.

Specifications

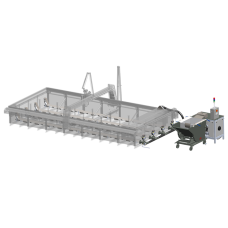

| FOOTPRINT (WITH PUMP & CONTROLLER) | 6,910 mm x 3,630 mm |

| HEIGHT (WITH SCISSOR PLUMBING) | 2,970 mm |

| OPERATING WEIGHT | 16,383 kg |

| WEIGHT (TANK EMPTY) | 3,855 kg |

| X-Y CUTTING TRAVEL* | 3,040 mm x 1,570 mm |

| Z-AXIS TRAVEL (WITH MOTORIZED Z AXIS)* | 304 mm |

| TABLE SIZE | 3,810 mm x 1,880 mm |

* Accessories may reduce travel. Accuracy specifications are at 72° F (22° C).

Model Specs

| MATERIAL SUPPORTS SLATS | 4" x 1/8" Galvanized Steel |

| MAXIMUM SUPPORTED MATERIAL LOAD | 1,950 kg/sq meter |

| ELECTRICAL REQUIREMENTS | 3-Phase, 380-480 VAC ±10%, 50-60 Hz |

| NOISE LEVEL | Below 80 dBA at one meter for submerged cutting |

| SPEED | 8,890 mm/min |

| LINEAR POSITIONAL ACCURACY* | ±0.025 mm |

| REPEATABILITY* | ±0.025 mm |

| BALLBAR CIRCULARITY* | ±0.0635 mm |

Waterjet system includes pump and software.

Contact ROMAX about optional accessories for your OptiMAX

PUMP INFO

| ENDUROMAX 50 HP | ENDUROMAX 40 HP | ENDUROMAX 30 HP | |

| MOTOR POWER | 50 HP (37kW) | 40 HP (30kW) | 30 HP (22 kW) |

| MAX JET POWER | 42.5 HP (31.5 kW) | 34.0 HP (34 kW) | 25.5 HP (18.7 kW) |

| OUTPUT PRESSURE | 60,000 psi | 60,000 psi | 60,000 psi |

| ORIFICE & FLOW RATE | 0.41 mm / 4.54 lpm | 0.36 mm / 3.48 lpm | 0.30 mm / 2.54 lpm |

| FOOTPRINT LXWXH | 1,676mm x 914mm x 978mm | 1,676mm x 914mm x 978mm | 1,676mm x 914mm x 978mm |

Maximized uptime with 1,000 hours between maintenance cycles

Increased production by delivering 30% more cutting power

Variable Frequency Drive reduces startup power consumption and maximizes operating flexibility

Additional pump configurations available.

** Recommended maximum orifice size. Smaller orifice sizes have a corresponding lower flow rate.

Standard Features

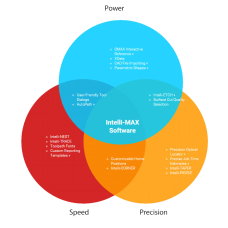

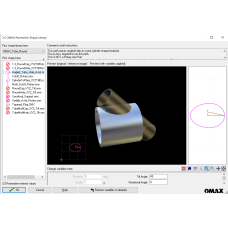

Backed by our exclusive IntelliMAX Premium Software

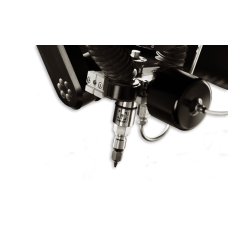

Exclusive IntelliTRAX abrasive jet linear drive system provides 350 in/min (8.9 m/min) traverse with real-time closed-loop positioning feedback

12-inch (305 mm) programmable Z axis travel with lowest ceiling height requirement design in the industry.

Standard Rapid Water Level Control for cleaner, safer, and quieter submerged cutting completes most work below 80 dBA

Standard scissor-style hard plumbing.

OMAX Benefits

Designed and manufactured at the OMAX factory in Kent, Washington, USA

Does not create heat-affected zones or mechanical stresses

Machines a wide range of materials and thicknesses, from metals and composites to glass and plastics

No tool changes & minimal fixturing dramatically reduce setup

Service & Training

Unlimited free training for the life of your machine

Unlimited software upgrades for the life of the machine

2-year / 4000-hour limited warranty

3 days of onsite training upon installation

English

English  Bulgarian

Bulgarian Romana

Romana

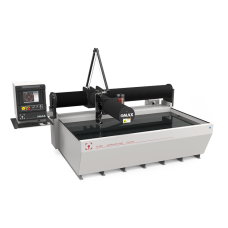

OMAX Micromax

OMAX Micromax OMAX 2626

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

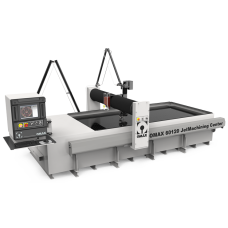

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

OptiMAX 80X MAXIEM 1515X

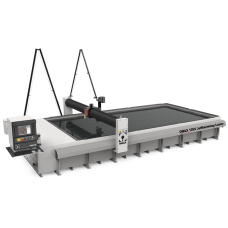

MAXIEM 1515X MAXIEM 1530X

MAXIEM 1530X MAXIEM 2030X

MAXIEM 2030X MAXIEM 2040X

MAXIEM 2040X MAXIEM 2060X

MAXIEM 2060X MAXIEM 3060X

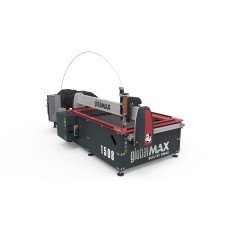

MAXIEM 3060X GlobalMAX 1508

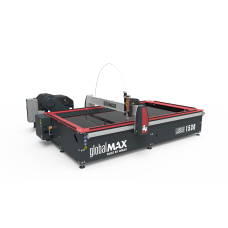

GlobalMAX 1508 GlobalMAX 1530

GlobalMAX 1530 GlobalMAX 2040

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

Reports Supported File Formats

Supported File Formats Tools

Tools Layout

Layout Make

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program