The integrated monitoring tools of the Intelli-MAX Software Suite keep you connected to your machine to maximize your production. From advanced predictive system monitoring to video-based remote monitoring tools, Intelli-MAX gives you extensive knowledge on the state of your system.

Intelli-VISOR System Monitoring

The Intelli-VISOR® System Monitoring Package runs on the OMAX PC controller as a system application in tandem with MAKE to offer additional machine feedback and allow you to set alerts and pauses. Intelli-VISOR provides a common interface for monitoring various sources and accommodates new monitoring packages and accessories on the fly, no updates required.

The software contains a list of watch parameters called modules which process inputs and can optionally store limit thresholds (e.g. low warning, low error, high warning, high error). For each of these limits, automated alert messages can be configured to show on-screen, log to a file, or send via email or mobile SMS (requires Internet connection on machine).

MTConnect

MTConnect is an AMT (Association for Manufacturing Technology) communication standard that allows various automated machine tools to output data in a common format that enables third-party programs or agents to pick up and present the data in a manner meaningful to the user. All new OMAX and MAXIEM JetMachining Centers feature an “adapter” that processes messages the machine generates and converts these messages into useful data for designated third-party applications or agents.

OMAX Watcher

OMAX Watcher is a program that allows remote video monitoring of the OMAX or MAXIEM machine's status. This means you can be at a computer in a different room or in a different building and still see what the machine is doing.

This feature can be used to:

- Check if the machine is busy before going to make a part (also find out how much longer the current part will take, which helps you plan).

- Monitor the making of a part when not in the room.

- Check the status of several OMAX machines, ensuring things are running smoothly.

- Pause the machine from your office computer.

Not all options are available on MAXIEM JetMachining Centers. Contact your sales representative for more information.

English

English  Bulgarian

Bulgarian Romana

Romana

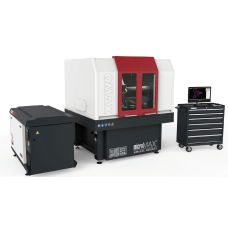

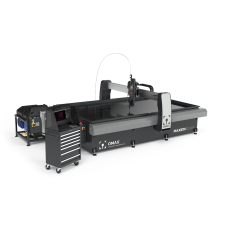

OMAX Micromax

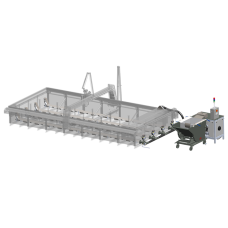

OMAX Micromax OMAX 2626

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

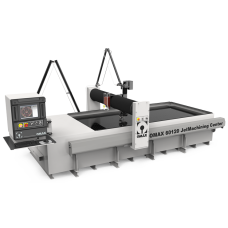

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

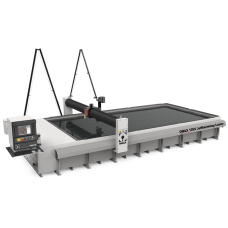

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

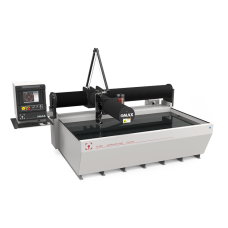

OptiMAX 80X MAXIEM 1515X

MAXIEM 1515X MAXIEM 1530X

MAXIEM 1530X MAXIEM 2030X

MAXIEM 2030X MAXIEM 2040X

MAXIEM 2040X MAXIEM 2060X

MAXIEM 2060X MAXIEM 3060X

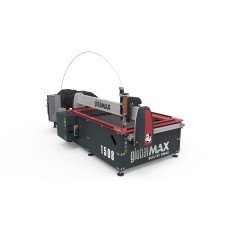

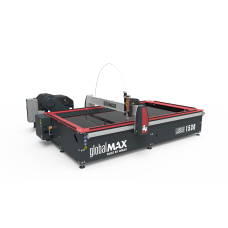

MAXIEM 3060X GlobalMAX 1508

GlobalMAX 1508 GlobalMAX 1530

GlobalMAX 1530 GlobalMAX 2040

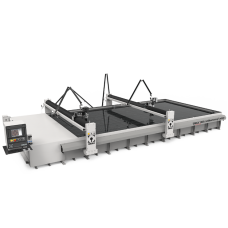

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

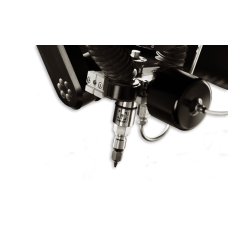

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

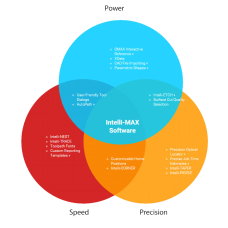

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

Reports Supported File Formats

Supported File Formats Tools

Tools Layout

Layout Make

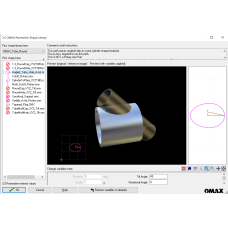

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program