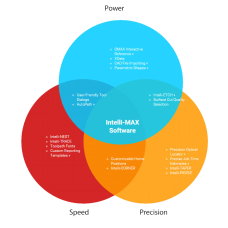

Simple, fast and precise. The OMAX Intelli-MAX Software Suite delivers extraordinary power and performance while remaining intuitive and easy to use. From creating a drawing to importing part files, Intelli-MAX easily takes your design and prepares it for machining. Powerful cutting enhancements complete the process, quickly converting your design into reality with efficiency and precision.

"We took the best software in the industry and made it even better."

Carl Olsen

Lead Software Engineer, OMAX Corp

4-th Generation Cutting Model

An abrasive waterjet stream is driven by the laws of physics, and defining those rules is essential to squeezing the maximum potential from your abrasive waterjet. We lead the world in waterjet control software, and continuously improve our cutting model based on the latest advancements in research. The current 4th Generation Cutting Model builds upon years of real-world data to deliver precise predictability in cutting speeds, taper and jet lag, all to deliver an optimum tool path with the industry’s highest levels of speed and performance.

Highly advanced cutting optimizations further enhance performance. Lead optimizations are automatically applied to maximize pierce speed for the given cut conditions. Corner passing greatly increases overall machining speed, while advanced Intelli-CORNER strategies examine the geometry of the corner and apply enhancements based on jet behavior and part shape to maintain precision while at the same time gaining speed. Tilt forward optimizations optimizes the angle of the jet to produce the least amount of trailing lag for even more speed. All of these optimizations can equal significant reductions in total cut times, save time and money, while maintaining high precision, maximizing your productivity.

Free Software Upgrades for Life

For over 20 years, OMAX has stood behind its products. A prominent highlight of that support is the OMAX Technology Guarantee. Unmatched in the industry, the OMAX Technology Guarantee provides every original OMAX JetMachining Center owner free software upgrades for the life of the machine. Since we are constantly improving and expanding our software, this means your OMAX always has the latest enhancements and cutting performance, maximizing your productivity and expanding the potential of your abrasive waterjet. Free training, both at the OMAX campus and in online eLearning modules, ensures that you stay current with the latest technology.

OMAX Interactive Reference (OIR)

The most comprehensive interactive waterjet reference available, the OIR features articles, videos, tutorials, a developer’s guide, teachings on the fundamentals of abrasivejet machining, tips and techniques for faster cutting and higher precision, and much more. A comprehensive index and powerful search function make finding the information you need simple and fast.

English

English  Bulgarian

Bulgarian Romana

Romana

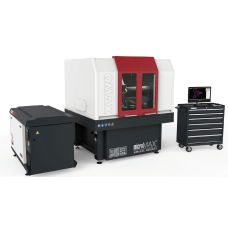

OMAX Micromax

OMAX Micromax OMAX 2626

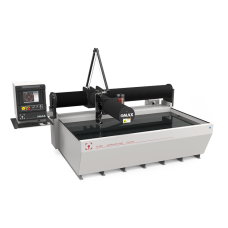

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

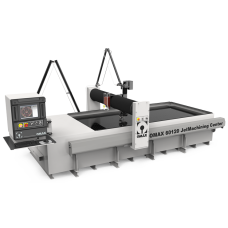

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

OptiMAX 80X MAXIEM 1515X

MAXIEM 1515X MAXIEM 1530X

MAXIEM 1530X MAXIEM 2030X

MAXIEM 2030X MAXIEM 2040X

MAXIEM 2040X MAXIEM 2060X

MAXIEM 2060X MAXIEM 3060X

MAXIEM 3060X GlobalMAX 1508

GlobalMAX 1508 GlobalMAX 1530

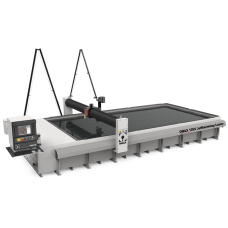

GlobalMAX 1530 GlobalMAX 2040

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

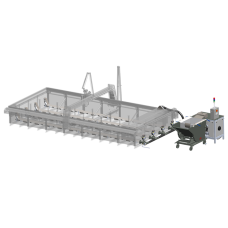

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

Reports Supported File Formats

Supported File Formats Tools

Tools Layout

Layout Make

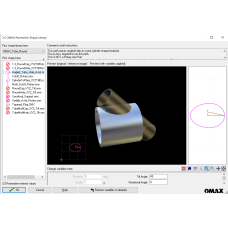

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program