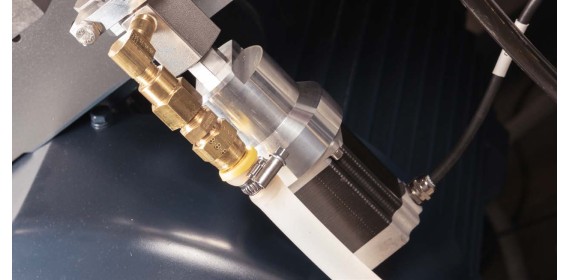

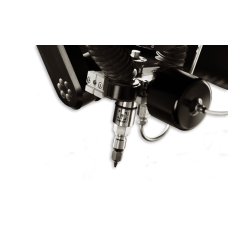

With system uptime a critical requirement for waterjet operators, OMAX developed the EnduroMAX technology to extend pump life and reduce maintenance cycles. Utilizing advanced materials and innovative engineering while maintaining the tradition of OMAX durability, the EnduroMAX pump simplifies maintenance and reduces downtime.

5-SERIES: BEYOND DIRECT DRIVE

Developed alongside the OptiMAX JetMachining Center, the EnduroMAX 5-Series takes all the benefits of the original EnduroMAX and dials them up. Designed to further reduce operator involvement, the EnduroMAX 5-Series features a motorized adjustable dump orifice and complete software control that automatically adjusts pressure settings, reducing fluctuations and extending pump life. The result is a highly efficient pump system with reduced dependency on the operator that maximizes production.

ENDUROMAX® TECHNOLOGY

With system uptime a critical requirement for waterjet operators, OMAX developed the EnduroMAX technology to extend pump life and reduce maintenance cycles. Utilizing advanced materials and innovative engineering while maintaining the tradition of OMAX durability, the EnduroMAX pump simplifies maintenance and reduces downtime.

ENHANCED TECHNOLOGY

With Variable Frequency Drive technology, OMAX pumps maximize production potential with substantial energy savings by altering the speed of the motor based on demand. With the VFD, OMAX pumps can operate throughout a wide range of motor RPMs, resulting in precise pressure control. Varying the speed and torque of the electric motor reduces wear and tear on the motor and pump crankcase, limiting maintenance overhead. Whether adjusting for low pressure piercing of delicate materials or dialing in pump pressure for maintenance longevity, VFD technology provides the user the flexibility to adapt to their specific needs and requirements.

| MOTOR POWER | MAXIMUM JETPOWER *1 | OUTPUT PRESSURE | ORIFICE AND FLOW RATE *2 | |

| 30 HP (22 kW) | 25.5 HP (18.7 kW) | 60,000 psi | 0.012” / 0.67 gpm (0.30mm / 2.54 lpm) | |

| ENDUROMAX 5-SERIES *3 | 40 HP (30 kW) | 34.0 HP (25.5 kW) | 60,000 psi | 0.014” / 0.92 gpm (0.36mm / 3.48 lpm) |

| 50 HP (37 kW) | 42.5 HP (31.5 kW) | 60,000 psi | 0.016” / 1.20 gpm (0.41mm / 4.54 lpm) |

1 JetPower is directly proportional to the water pressure at the nozzle times the volume flow rate of the waterjet stream.

2 Recommended maximum orifice size. Smaller orifice sizes have a corresponding lower flow rate.

3 EnduroMAX 5-Series pumps are only available on OptiMAX JetMachining Centers

All OMAX Direct Drive Pumps are compact, quiet, efficient, easy to maintain and inexpensive to operate. EnduroMAX – Boasting 1,000 hours between maintenance cycles, the EnduroMAX’s simple yet robust design is specifically engineered to simplify maintenance through innovative features such as independent cylinders. Available in 100, 50, 40, and 30 HP options.

MAXIEM – Specifically designed for the MAXIEM line of waterjets, the pump’s three cylinders are coordinated to provide a smooth high pressure output flow. Available in 40, 30, and 20 HP options.

GlobalMAX – A simplified direct drive pump specifically paired with the GlobalMAX waterjet line. Available in 30, 20 and 10 HP options.

PUMP EFFICIENCY COMPARISON

| PUMP TYPE | PRESSURE (KSI) | ORIFICE (IN.) | HYDRAULIC HP | EFFICIENCY |

| OMAX ENDUROMAX | 60 | 0.016 | 41.9 | 83.8% |

| COMPETITOR A | 87 | 0.01 | 28.6 | 57.2% |

| COMPETITOR B & C | 60 | 0.014 | 32.1 | 64.2% |

CUT FASTER. SPEND LESS.

OMAX’s direct drive pumps are the most efficient pumps on the market. With the same configuration in pressure and motor horsepower, higher efficiency pumps lead to an increase in cutting speed, resulting in less production cost and increased output. For an in depth look at how OMAX Pump Technology stacks up against the competition read the white paper.

Direct drive pumps don’t use hydraulic oil, so there is no need for costly chemical disposal when conducting maintenance. Also, the water and power consumption of a direct-drive pump is significantly less than other types of waterjet pumps.

English

English  Bulgarian

Bulgarian Romana

Romana

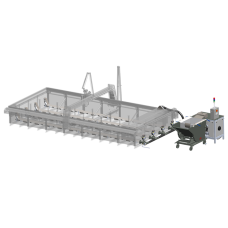

OMAX Micromax

OMAX Micromax OMAX 2626

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

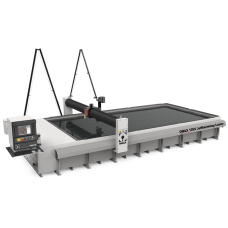

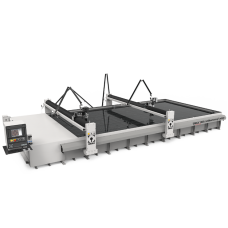

OptiMAX 80X MAXIEM 1515

MAXIEM 1515 MAXIEM 1530

MAXIEM 1530 MAXIEM 2030

MAXIEM 2030 MAXIEM 2040

MAXIEM 2040 MAXIEM 2060

MAXIEM 2060 MAXIEM 2080

MAXIEM 2080 MAXIEM 3060

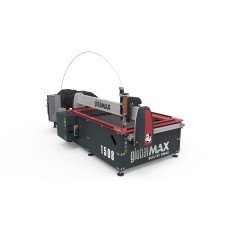

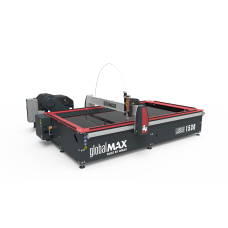

MAXIEM 3060 GlobalMAX 1508

GlobalMAX 1508 GlobalMAX 1530

GlobalMAX 1530 GlobalMAX 2040

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

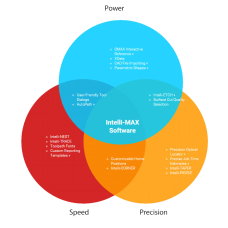

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

Reports Supported File Formats

Supported File Formats Tools

Tools Layout

Layout Make

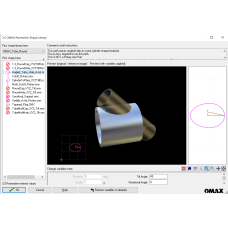

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program

-1200x415.jpg)