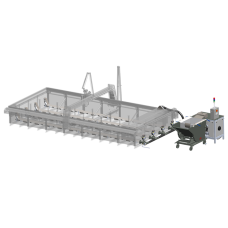

The PLC-controlled Large Solids Removal System (LSRS) provides precise control over evacuation rate, zone selection, and duration for efficient removal of spent abrasive from a large-bed waterjet catcher tank. The LSRS gives the user operational flexibility by allowing placement of the LSRS up to 100 feet (over 30 meters) away from the JetMachining Center.

Benefits & Features

- cUL-US compliant

- Efficient and rapid cleaning of a large JetMachining Center

- Automated PLC control during system operation

- Standard Hopper can collect 2,200 lb (1,000 kg) of abrasive in industry standard bag size

- Skid & Hopper Unit can be located remotely, up to 100 ft (30.5 m) for optimum facility placement

- 1.5 HP diaphragm pumps provides strong suction power

- Abrasive removal rates up to 30 lb/min (13.6 kg/min)

- Provides easy, economical way to clean the Catcher Tank with minimal downtime

- Utilizes minimal floor space for large table application

- Productively removes both large and fine particles

REQUIREMENTS

- 380-460 VAC, 3 Phase, 50/60 Hz, 15A

- Install according to local electrical code

English

English  Bulgarian

Bulgarian Romana

Romana

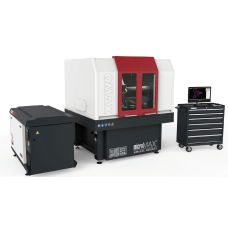

OMAX Micromax

OMAX Micromax OMAX 2626

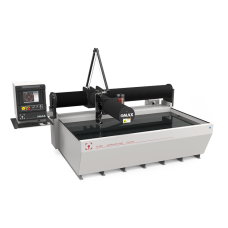

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

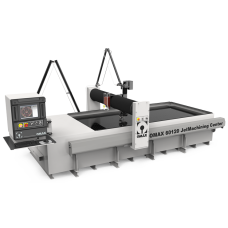

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

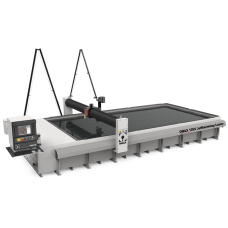

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

OptiMAX 80X MAXIEM 1515

MAXIEM 1515 MAXIEM 1530

MAXIEM 1530 MAXIEM 2030

MAXIEM 2030 MAXIEM 2040

MAXIEM 2040 MAXIEM 2060

MAXIEM 2060 MAXIEM 2080

MAXIEM 2080 MAXIEM 3060

MAXIEM 3060 GlobalMAX 1508

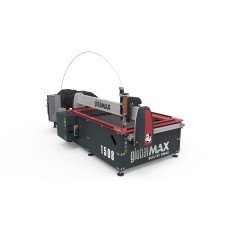

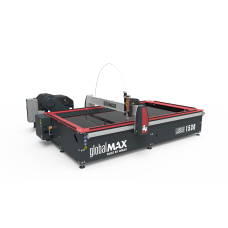

GlobalMAX 1508 GlobalMAX 1530

GlobalMAX 1530 GlobalMAX 2040

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

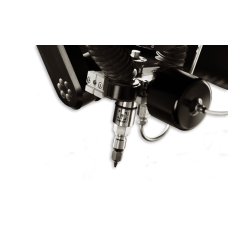

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

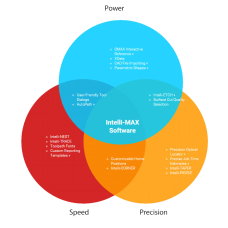

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

Reports Supported File Formats

Supported File Formats Tools

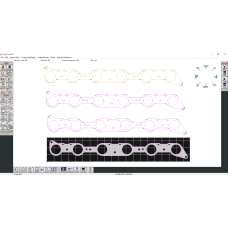

Tools Layout

Layout Make

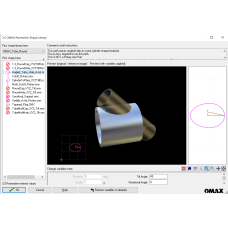

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program