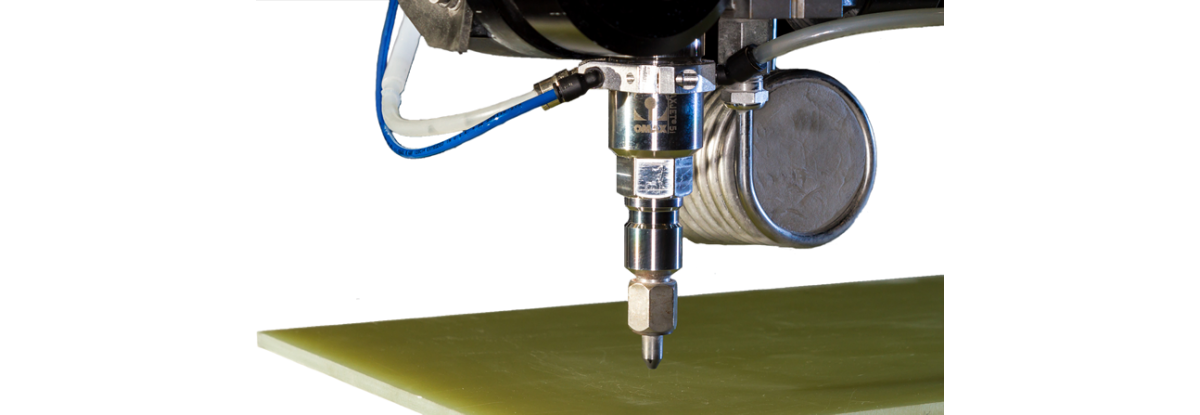

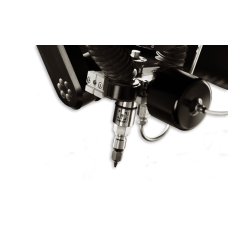

The OMAX Vacuum Assist accessory is the ideal abrasive waterjet solution for piercing brittle materials, advanced composites, challenging laminates, and more. While using lower pressure can generally pierce some brittle materials, the pressure of the jet can cause delamination if the abrasive feed is delayed even slightly. The OMAX Vacuum Assist eliminates that delay, allowing for consistent automatic piercing of composites, laminates, and other brittle materials. Designed to work on both cantilever and bridge machines in the OMAX and MAXIEM product line, the OMAX Vacuum Assist can increase production and reduce material waste for maximum part processing yields.

Benefits & Features

- Assist low-pressure piercing of delicate materials such as composites and brittle materials with low tensile strength

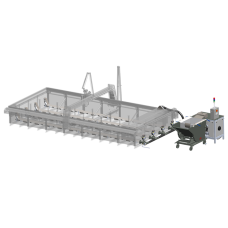

- Works on both OMAX and MAXIEM JetMachining Centers, including the MicroMAX

- Minimal floor space requirements

- Low-pressure stationary piercing can help improve the circularity and edge quality of small holes

- Works with Motorized Z Axis, Tilt-A-Jet, and A-Jet cutting heads

- Precise on/off cycles to prevent excess garnet usage

- Aids in piercing laminates with low adhesive strength between layers of thin materials and/or coating and substrate

- Automatic dynamic pressure adjustments

- Available in a wide range of nozzle orifice sizes, from 0.007” to 0.016”, with mixing tubes from 0.015” to 0.048”

- Visible pressure gauge to verify correct pressure settings

English

English  Bulgarian

Bulgarian Romana

Romana

OMAX Micromax

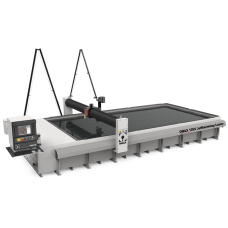

OMAX Micromax OMAX 2626

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

OptiMAX 80X MAXIEM 1515

MAXIEM 1515 MAXIEM 1530

MAXIEM 1530 MAXIEM 2030

MAXIEM 2030 MAXIEM 2040

MAXIEM 2040 MAXIEM 2060

MAXIEM 2060 MAXIEM 2080

MAXIEM 2080 MAXIEM 3060

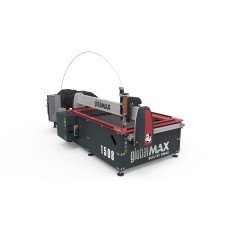

MAXIEM 3060 GlobalMAX 1508

GlobalMAX 1508 GlobalMAX 1530

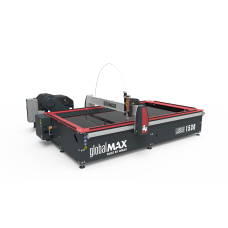

GlobalMAX 1530 GlobalMAX 2040

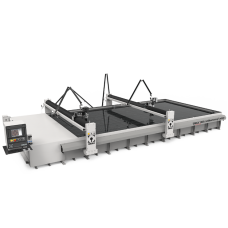

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

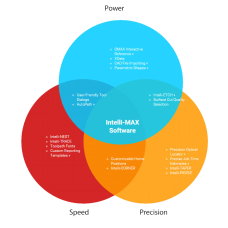

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

Reports Supported File Formats

Supported File Formats Tools

Tools Layout

Layout Make

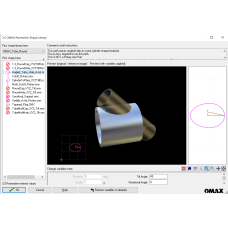

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program