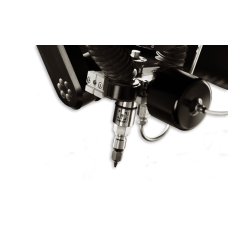

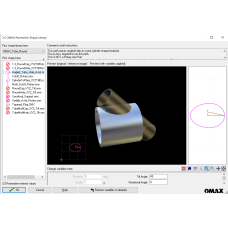

The Tilt-A-Jet represents the latest OMAX innovation in the continuing search for more accurate abrasive waterjet machining. The Tilt-A-Jet lets the OMAX JetMachining Center achieve virtually zero taper with most materials. The Tilt-A-Jet can position the nozzle at an angle calculated by the software to exactly offset the taper from the abrasivejet. Taper doesn't disappear--it just gets moved to the scrap part of the material, leaving your part with exactly square edges.

Benefits & Features

- Easily make interlocking pieces, dovetail fittings, and lead ins without taper to reduce secondary machining

- Tilting point positioned at material surface to reduce X-Y motion

- Easy to use, with no special programming required

- Continuously adjusts at thousands of points per inch along path

- Can be used on OMAX machines from the 2626 to the 160X

- Automatic re-squaring feature ensures nozzle is square to the table

- Ability to change angles quickly, further enhancing cutting speed

- Compatible with Precision Optical Locator and Rotary Axis

- Faster cutting of high precision taper free parts with no need to slow down to eliminate taper

- Servo-controlled programmable precision Z-axis with 150 mm of travel

- Faster cutting due to “tilt forward” capability

- Advanced servo design results in virtually zero backlash

- Programmable manual tilt up to ±9° for the maximum tilt angle

- Automatic taper elimination without any programming

Options

- Terrain Follower automatically adjusts to accommodate warped flat plate

- Rotary Axis allows for complex 6-axis 3D parts and precision beveled pipe fittings

- 0.030" Fusible Mixing Tube for finer kerf size

REQUIREMENTS

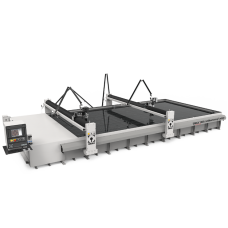

- A bridge-style OMAX JetMachining Center (for cantilever-style OMAX JetMachining Centers, contact an OMAX sales representative for details)

- OMAX 9-axis PC-based controller

- OMAX Intelli-MAX 18 Software Suite or later for taper compensation

English

English  Bulgarian

Bulgarian Romana

Romana

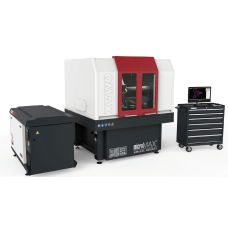

OMAX Micromax

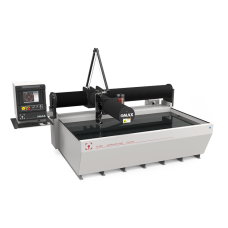

OMAX Micromax OMAX 2626

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

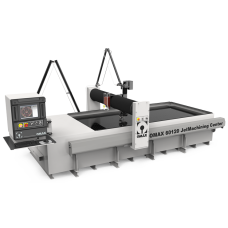

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

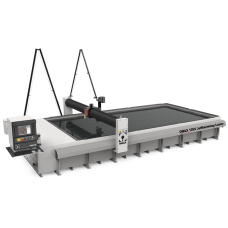

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

OptiMAX 80X MAXIEM 1515

MAXIEM 1515 MAXIEM 1530

MAXIEM 1530 MAXIEM 2030

MAXIEM 2030 MAXIEM 2040

MAXIEM 2040 MAXIEM 2060

MAXIEM 2060 MAXIEM 2080

MAXIEM 2080 MAXIEM 3060

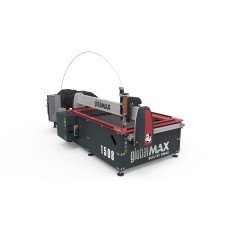

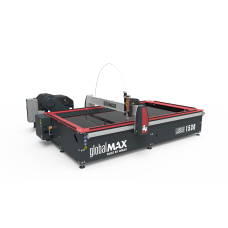

MAXIEM 3060 GlobalMAX 1508

GlobalMAX 1508 GlobalMAX 1530

GlobalMAX 1530 GlobalMAX 2040

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

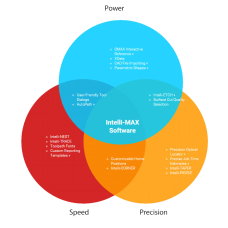

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

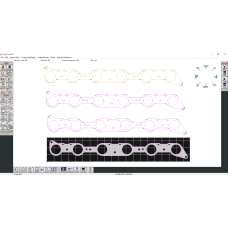

Reports Supported File Formats

Supported File Formats Tools

Tools Layout

Layout Make

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program