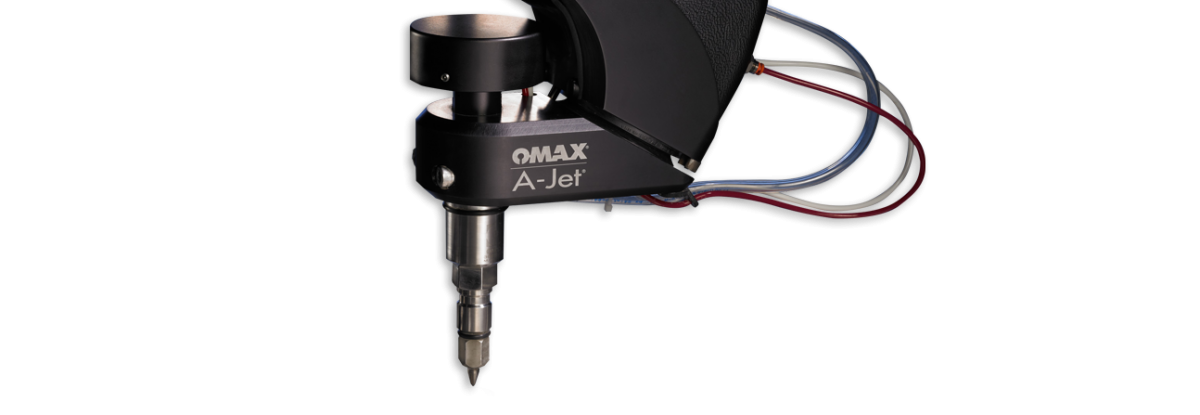

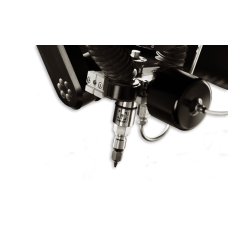

The A-Jet is a completely software-controlled multi-axis cutting head that greatly expands the versatility of the OMAX JetMachining Center. With a cutting range from 0° to 60°, the A-Jet can easily cut beveled edges, angled sides, and countersinks. Advanced features in the Intelli-MAX Software Suite allow the A-Jet to compensate for taper and easily create complex 3D shapes. With its inherent high level of positioning accuracy, the A-Jet is capable of cutting parts that require no secondary finishing, significantly reducing part production time.

Benefits & Features

- Eliminates secondary machining and grinding for fabrication processes, ideal for common welding projects

- Easily creates countersinks and weld-ready edges

- Precision angular motion can create unique 3D parts

- Fully automatic taper compensation to minimize taper on finished parts

- OMAX-unique High Angle Fusible Mixing Tube protects precision mechanism

- Cutting angle ranges from 0° to 60°

- Three modes of taper compensation

- Supplied with a MAXJET 5i Nozzle, which includes an OMAX High Angle Fusible Mixing Tube

- Designed for high flow/high power abrasive waterjet applications with multiple pumps by using large diameter tubing with minimal pressure loss

- Features a fixed focal point design, where the XYZ axes do not need to move as the head tilts

Options

- Terrain Follower automatically adjusts to accommodate warped flat plate

- Rotary Axis allows for complex 6-axis 3D parts and precision beveled pipe fittings

- 0.030" Fusible Mixing Tube for finer kerf size

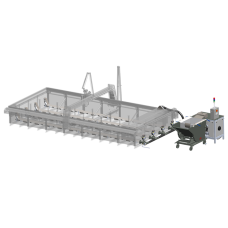

- A bridge-style OMAX JetMachining Center (for cantilever-style OMAX JetMachining Centers, contact an OMAX sales representative for details)

- OMAX 9-axis PC-based controller

- OMAX Intelli-MAX 18 Software Suite or later for taper compensation

Taper Compensation

The A-Jet is capable of fully automatic taper compensation, resulting in parts with square edges. Taper compensation is fully software controlled and requires no extra programming, simplifying production and reducing secondary machining.

Weld Prep Cutting

The A-Jet makes cutting bevels simple, and software controls help to eliminate taper.

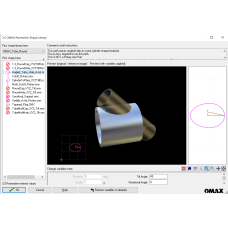

3D Machining

Through advanced yet easy-to-use software enhancements such as XData, the A-Jet is capable of cutting complex three dimensional shapes quickly and accurately. Simply set the cutting angle to the drawing entity, and the software automatically sets the A-Jet to accurately and quickly cut the shape.

English

English  Bulgarian

Bulgarian Romana

Romana

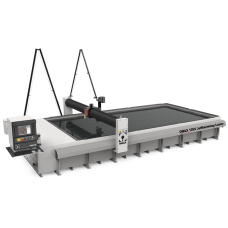

OMAX Micromax

OMAX Micromax OMAX 2626

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

OptiMAX 80X MAXIEM 1515

MAXIEM 1515 MAXIEM 1530

MAXIEM 1530 MAXIEM 2030

MAXIEM 2030 MAXIEM 2040

MAXIEM 2040 MAXIEM 2060

MAXIEM 2060 MAXIEM 2080

MAXIEM 2080 MAXIEM 3060

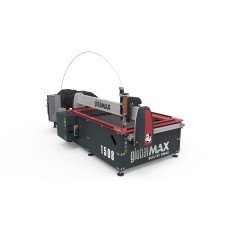

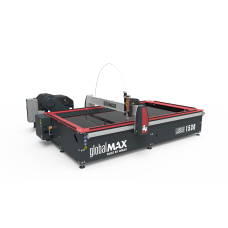

MAXIEM 3060 GlobalMAX 1508

GlobalMAX 1508 GlobalMAX 1530

GlobalMAX 1530 GlobalMAX 2040

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

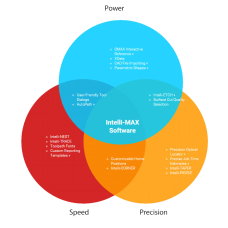

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

Reports Supported File Formats

Supported File Formats Tools

Tools Layout

Layout Make

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program