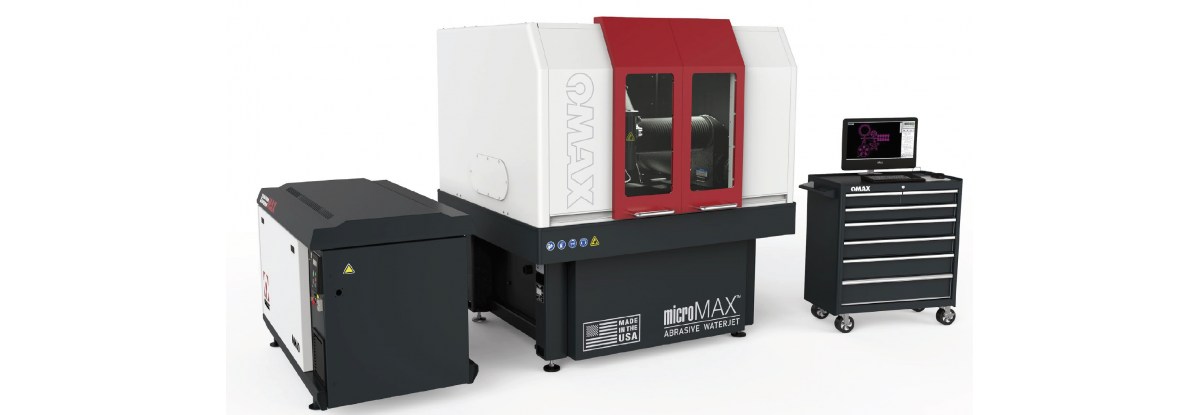

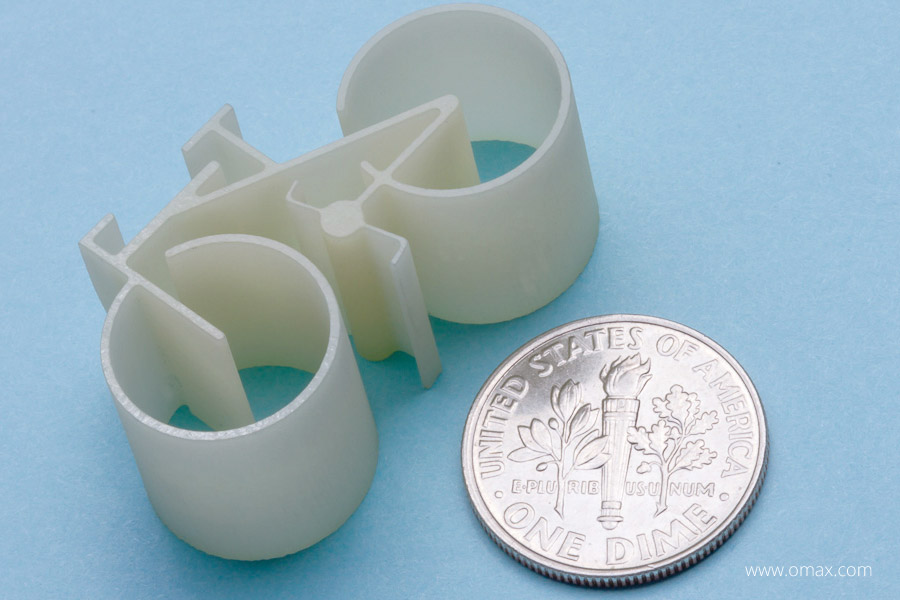

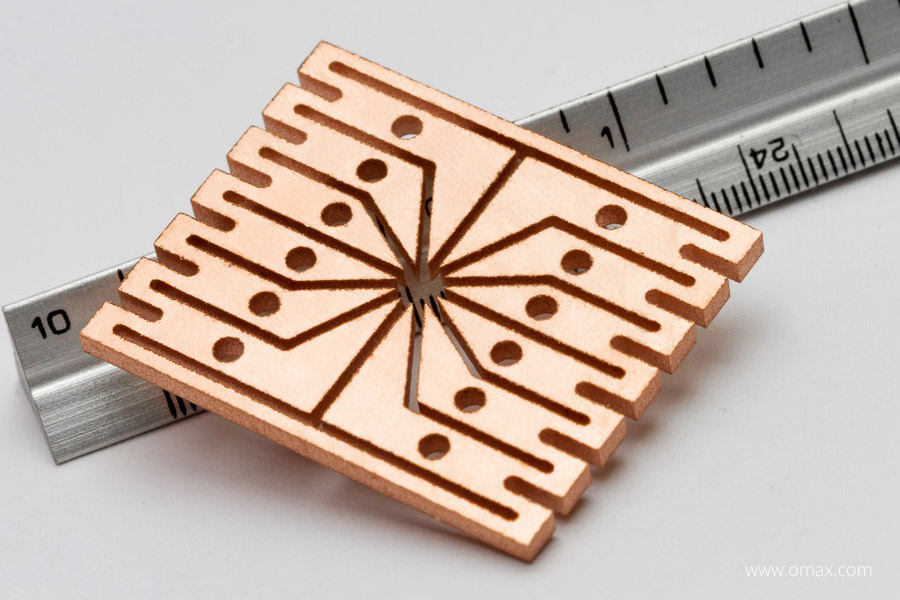

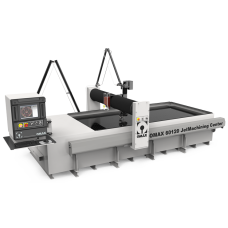

The MicroMAX™ JetMachining® Center is the ideal solution for ultra-precision abrasive waterjet machining. Utilizing advanced high precision linear encoders, innovative vibration isolation, and proven software control systems, the MicroMAX JetMachining Center is capable of a positioning accuracy of less than five microns while retaining all the advantages of abrasive waterjet machining. The MicroMAX JetMachining Center cuts without heat affected zone (HAZ), so no secondary processing is required. The MicroMAX JetMachining Center can machine stainless steel, titanium, carbon fiber, PEEK, glass, nitinol, graphite, copper, composites, laminates, and more, with high precision and smooth finishing, for either prototyping or production.

Specifications

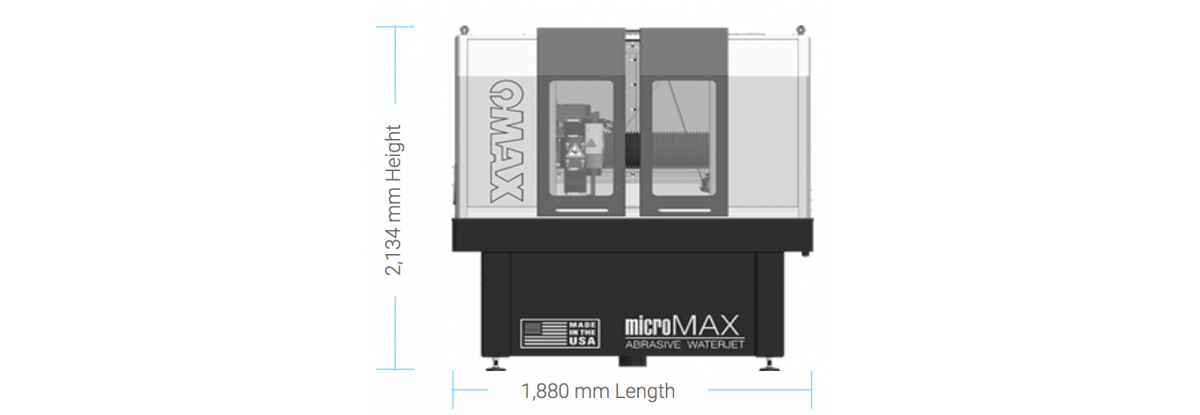

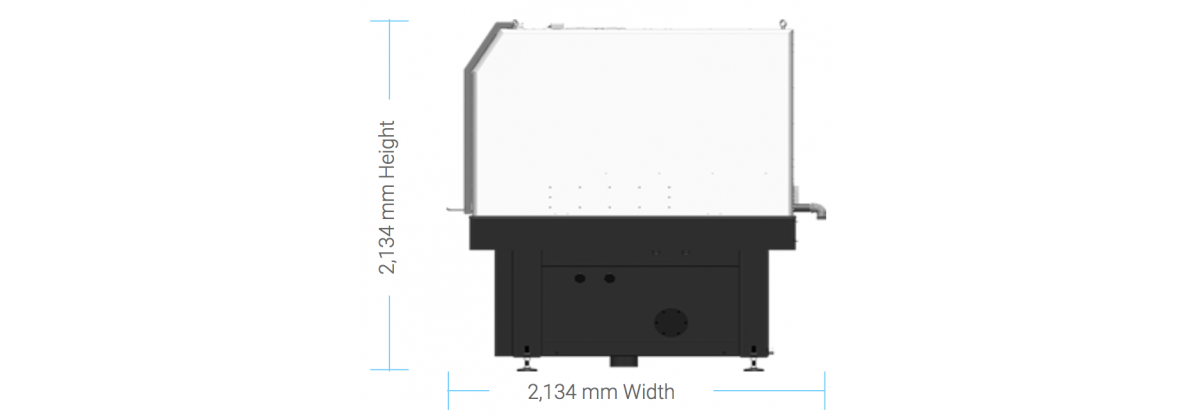

| Footprint * – (L x W) | 1,880 mm x 2,134 mm |

| Height ** | 2,134 mm |

| Weight (tank empty) | 1,724 kg |

| X-Y Cutting Envelope *** | 635 mm x 635 mm |

| Z-Axis Travel *** | 114 mm |

| Table Size – (L x W) | 889 mm x 914 mm |

| Speed | 2,540 mm/min |

| Repeatability | ±0.0025 mm |

| Ballbar Circularity | ±0.0152 µm |

Applications

With its versatility, the OMAX MicroMAX is ideally suited to turn ideas into reality. With its small footprint, high precision, and fast cutting, it is an ideal research and development, rapid prototyping, and production waterjet machine for industries such as medical, electronics, aerospace, energy production/storage and more. Easily machine prototype parts in one material for testing, then manufacture production samples from another material, all while maintaining the same precision and preserving the material integrity.

Resources

English

English  Bulgarian

Bulgarian Romana

Romana

OMAX Micromax

OMAX Micromax OMAX 2626

OMAX 2626 OMAX 2652

OMAX 2652 OMAX 5555

OMAX 5555 OMAX 55100

OMAX 55100 OMAX 60120

OMAX 60120 OMAX 80X Series

OMAX 80X Series OMAX 120X Series

OMAX 120X Series OMAX 160X Series

OMAX 160X Series OMAX - Mobile Units

OMAX - Mobile Units OptiMAX 60X

OptiMAX 60X OptiMAX 80X

OptiMAX 80X MAXIEM 1515

MAXIEM 1515 MAXIEM 1530

MAXIEM 1530 MAXIEM 2030

MAXIEM 2030 MAXIEM 2040

MAXIEM 2040 MAXIEM 2060

MAXIEM 2060 MAXIEM 2080

MAXIEM 2080 MAXIEM 3060

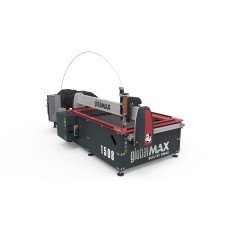

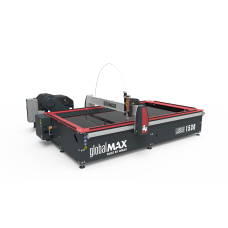

MAXIEM 3060 GlobalMAX 1508

GlobalMAX 1508 GlobalMAX 1530

GlobalMAX 1530 GlobalMAX 2040

GlobalMAX 2040 Bridges

Bridges Multi-Axis Cutting

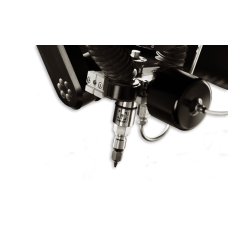

Multi-Axis Cutting Nozzle & Y-Carriage Accessories

Nozzle & Y-Carriage Accessories Nozzles

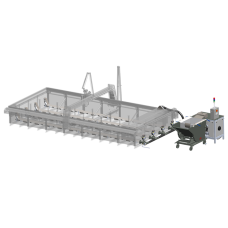

Nozzles Tank Enhancements

Tank Enhancements Water Treatment Equipment

Water Treatment Equipment 100HP Direct Drive Pump

100HP Direct Drive Pump-228x228.jpg) ENDUROMAX 5-SERIES

ENDUROMAX 5-SERIES EnduroMAX Direct Drive Pumps

EnduroMAX Direct Drive Pumps MAXIEM Direct Drive Pump

MAXIEM Direct Drive Pump OMAX DynaMAX INTENSIFIER PUMPS

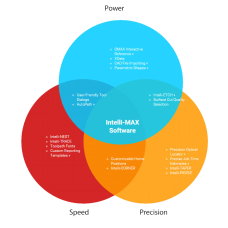

OMAX DynaMAX INTENSIFIER PUMPS Inteli-max Software

Inteli-max Software Optimized for Speed, Power, and Precision

Optimized for Speed, Power, and Precision Predictive and Preventative Monitoring

Predictive and Preventative Monitoring Reports

Reports Supported File Formats

Supported File Formats Tools

Tools Layout

Layout Make

Make Intelli-cam

Intelli-cam Intelli-visor

Intelli-visor Why intelli-max

Why intelli-max OMAX Compatible Program

OMAX Compatible Program